Khoom Carbide Qws

![]() Taw qhia Cov Khoom Carbide Qws

Taw qhia Cov Khoom Carbide Qws

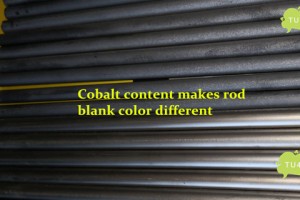

Cov pas nrig carbide feem ntau yog ua los ntawm tungsten carbide, binder hlau cobalt thiab qee yam khoom siv ntxiv uas tsim nyog raws li cov mis xav tau, los ntawm cov ntaub ntawv sib xyaw, extruding, pre-sinter, hloov kho cov qauv tsim cov txheej txheem ces sintered hauv siab. Nrog cov cim ntawm qhov nyuaj, lub zog siab, tshuaj lom neeg ruaj khov, nthuav dav coefficient, hluav taws xob thiab kev ua kom sov, sintered tungsten carbide rods tau siv dav hauv thaj chaw tsim khoom, piv txwv li, txhawm rau ua micro laum hauv PCB kev lag luam, electrode bar hauv zej zog kho qhov muag. kev lag luam, laum, laum cov khoom lag luam, cov lus qhia, pusher, hnav cov khoom tiv taus qhov tseeb, CNC reamer thiab cov hniav nrog lub qhov txias hauv qhov kev lag luam ua haujlwm.

Raws li cov chaw khaws khoom carbide, Toonney tungsten hlau cog chaw tsim khoom ntau yam ntawm tungsten alloy suav nrog cov pas nrig, cov pas nrig nrog ncaj/muab kauv txias lub qhov, zoo li tus pas nrig raws li cov neeg siv khoom xav tau thiab T zoo li.

Khoom tungsten carbide pas nrig, tsis muaj cov dej txias txias hauv. Peb muaj 10 qib khoom siv mis rau siv feem ntau, piv txwv li, pas nrig rau PCB micro laum, micro milling cutter, carbide pom hniav, xyaum ua haujlwm aluminium alloy, tooj liab puag alloy, hlau puag alloy thiab; wolfram carbide thiab lwm yam. Peb nruj tswj hwm qhov ua tau zoo hauv txhua kauj ruam tsim nyog, peb tuaj yeem hais qhov zoo yog qhov zoo uas ua rau peb sawv hauv qhov kev lag luam no.

Wolfram carbide: Wolfram carbide yog cov sib xyaw ua ke ntawm wolfram thiab carbide. Nws yog ib qho xim dub hexagonal nrog cov xim ci ci, ntawm qhov tawv tawv zoo ib yam li pob zeb diamond. Wolfram carbide yog tus coj zoo ntawm hluav taws xob thiab cua sov, tsis tuaj yeem yaj hauv dej, hydrochloric acid lossis sulfuric acid, tab sis yooj yim kom yaj hauv cov kua nitric acid sib xyaw. thiab hydrofluoric acid. Ntshiab wolfram carbide tsis yooj yim, tab sis ntxiv titanium lossis cobalt thiab sintered, qhov ntxhib yuav ntau dua. Wolfram carbide tseem hu ua tungsten carbide.

Tungsten hlau/Tungsten metallic:Tungsten tseem hu ua wolfram, feem ntau daim ntawv tungsten hlau hauv daim ntawv thov kev lag luam yog tungsten carbide. Toonney tungsten hlau Hoobkas tau tsim cov khoom siv carbide ruaj khov tau ntau xyoo thiab tau txais lub koob npe zoo hauv tsev thiab txawv teb chaws.

Ntim Cov Lus Qhia: Lub hnab yas, tom qab ntawd tiv thaiv hauv npuas ua npuas, thaum kawg mus rau lub thawv sab nrauv.

Cov Qauv Tseem Ceeb:Cov khoom siv carbide uas tuaj yeem muaj los ntawm peb cov khoom lag luam ib txwm muaj, tuaj yeem muab ua piv txwv dawb. Rau cov khoom siv carbide ruaj khov nrog cov neeg siv khoom tshwj xeeb xav tau tshwj xeeb, yuav raug them. Tau kawg, cov neeg siv khoom yuav tsum them tus nqi thauj khoom. Feem ntau, lub sijhawm coj mus kuaj yuav nyob hauv 7 hnub ua haujlwm.

Yam tsawg kawg yuam kom muaj nuj nqis: Tsis muaj qhov txiav txim yam tsawg kawg nkaus kom muaj nuj nqis ntawm cov khoom siv carbide ruaj khov rau thawj qhov kev txiav txim plaub ntug. Tab sis ntawm qhov kev txiav txim zaum thib ob, tag nrho cov nyiaj ntawm cov khoom siv carbide ruaj khov yuav tsum tsis pub tsawg dua 1000 USD.

Lub sij hawm xa tuaj: 7-15 hnub ua haujlwm

![]() Txiav Cov Cuab Yeej Qib Qib thiab Daim Ntawv Thov

Txiav Cov Cuab Yeej Qib Qib thiab Daim Ntawv Thov

| Qib | Co % | Grain Siz (hli) | Ceev (g/cm3) | Hardness (HRA) | TRS (N/hli 2) |

| TU90 | 9.0 | 0.2 | 14.35 | 94.1 | 5200 |

| TX06 | 6.0 | 0.6 | 14.81 | 93.1 | 4000 |

| TU06 TSI | 6.0 | 0.4 | 14.8 | 94.3 | 4600 |

| TU08 ua | 8.0 | 0.4 | 14.52 | 93.5 | 4800 |

| TU08 TWS | 8.0 | 0.3 | 14.5 | 93.6 ib | 5000 |

| TU40 | 10.0 | 0.8 | 14.4 | 91.7 ib | 4600 |

| TU40F | 10.0 | 0.6 | 14.45 | 92.3 ib | 4600 |

| TU40S | 10.0 | 0.5 | 14.5 | 92.5 | 4800 |

| TU44 | 12.0 | 0.4 | 14.1 | 92.6 ib | 4800 |

| TU25 | 12.0 | 0.6 | 14.06 | 92.5 | 4200 |

| TU45 | 13.0 | 0.3 | 13.95 | 92.7 ib | 4800 |

| TU55 | 13.0 | 0.3 | 13.92 | 92.6 ib | 4800 |

![]() Recommanded Daim Ntawv Thov

Recommanded Daim Ntawv Thov

| Qib | Recommanded daim ntawv thov |

| TU90 | Rau kev txiav cov cuab yeej ua cov khoom siv quesnched (HRC65-70), cov tawv ntoo thiab cov tshuab ua kom siab zoo. Zoo heev rau cov tshuab txiav tiav machining 316L stinless steel |

| TX06 | Rau kev txiav cov cuab yeej ua haujlwm aluminium magnesium alloy, graphite thiab fiber ntau sib xyaw. |

| TU06 TSI | Rau PCB micro-laum thiab kawg zeb machining super siab hlua hlau |

| TU08 ua | Rau PCB micro-laum, mini milling cutter. |

| TU08 TWS | Rau micro PCB laum, txiav cov cuab yeej rau kev ua tiav cov khoom siv ua kom sov (HRC60-65), 316L stainless hlau, siab polishing hlau ntawv thiab silicon steel ntawv ntawm lub cev muaj zog. |

| TU40 | Rau kev siv me ntsis ntsis, kawg zeb thiab xuas nrig ntaus tuag. |

| TU40F | Rau kev siv me ntsis me ntsis, kawg zeb ua cov titanium alloy, stainless hlau thiab txho cam khwb cia hlau. |

| TU40S | Rau kev txiav cov cuab yeej ua haujlwm 316L stainless hlau, cov khoom siv zoo tshaj plaws rau cov khoom siv ib puag ncig. |

| TU44 | Rau kev txiav cov cuab yeej ua cov titanium alloy, tiv taus tshav kub, hlau tsis muaj hlau, quesnched steel (HRC55 thiab siab dua), txho cam khwb cia hlau. |

| TU25 | Rau kev txiav cov cuab yeej ua cov cua sov kho cov hlau (Hardness HRC45 thiab siab dua), cam khwb cia hlau, stainless hlau. |

| TU45 | Rau kev txiav cov cuab yeej ua cov titanium, tiv taus tshav kub, hlau tsis xeb, quesnched hlau (HRC60 thiab siab dua) |

| TU55 | Qib nrog qib liab-tawv, zoo rau kev txiav cov cuab yeej ua haujlwm kub tsis kam tiv taus hlau, quenched hlau (HRC60 thiab siab dua) thiab titanium alloy |

![]() Kev Qhia Tshwj Xeeb ntawm Cov Khoom Carbide Qws

Kev Qhia Tshwj Xeeb ntawm Cov Khoom Carbide Qws

| Dia. Ø hli |

Kev kam rau ua (mm) | Ntev (hli) | Tol. (Hli) | Dia.mm (hli) | Kev kam rau ua (mm) | Ntev (hli) | Tol. (Hli) |

| 2.0 | +0.30/+0.15 | 330 | 1.5 | 16.5 | +0.8/+0.3 | 330 | 1.5 |

| 2.5 | +0.30/+0.15 | 330 | 1.5 | 17.0 | +0.8/+0.3 | 330 | 1.5 |

| 3.0 | +0.50/+0.30 | 330 | 1.5 | 17.5 | +0.8/+0.3 | 330 | 1.5 |

| 3.5 | +0.50/+0.30 | 330 | 1.5 | 18.0 | +0.8/+0.3 | 330 | 1.5 |

| 4.0 | +0.50/+0.30 | 330 | 1.5 | 18.5 | +0.8/+0.3 | 330 | 1.5 |

| 4.5 | +0.50/+0.30 | 330 | 1.5 | 19.0 | +0.8/+0.3 | 330 | 1.5 |

| 5.0 | +0.50/+0.30 | 330 | 1.5 | 19.5 | +0.8/+0.3 | 330 | 1.5 |

| 5.5 | +0.50/+0.30 | 330 | 1.5 | 20.0 | +0.8/+0.3 | 330 | 1.5 |

| 6.0 | +0.50/+0.30 | 330 | 1.5 | 20.5 | +0.8/+0.3 | 330 | 1.5 |

| 6.5 | +0.50/+0.30 | 330 | 1.5 | 21.0 | +0.8/+0.3 | 330 | 1.5 |

| 7.0 | +0.50/+0.30 | 330 | 1.5 | 21.5 | +0.8/+0.3 | 330 | 1.5 |

| 7.5 | +0.50/+0.30 | 330 | 1.5 | 22.0 | +0.8/+0.3 | 330 | 1.5 |

| 8.0 | +0.50/+0.30 | 330 | 1.5 | 22.5 | +0.8/+0.3 | 330 | 1.5 |

| 8.5 | +0.50/+0.30 | 330 | 1.5 | 23.0 | +0.8/+0.3 | 330 | 1.5 |

| 9.0 | +0.60/+0.30 | 330 | 1.5 | 23.5 | +0.8/+0.3 | 330 | 1.5 |

| 9.5 | +0.60/+0.30 | 330 | 1.5 | 24.0 | +0.8/+0.3 | 330 | 1.5 |

| 10.0 | +0.60/+0.30 | 330 | 1.5 | 24.5 | +0.8/+0.3 | 330 | 1.5 |

| 10.5 | +0.60/+0.30 | 330 | 1.5 | 25.0 | +0.8/+0.3 | 330 | 1.5 |

| 11.0 | +0.60/+0.30 | 330 | 1.5 | 25.5 | +0.8/+0.3 | 330 | 1.5 |

| 11.5 | +0.60/+0.30 | 330 | 1.5 | 26.0 | +0.8/+0.3 | 330 | 1.5 |

| 12.0 | +0.60/+0.30 | 330 | 1.5 | 26.5 | +0.8/+0.3 | 330 | 1.5 |

| 12.5 | +0.60/+0.30 | 330 | 1.5 | 27.0 | +0.8/+0.3 | 330 | 1.5 |

| 13.0 | +0.60/+0.30 | 330 | 1.5 | 27.5 | +0.8/+0.3 | 330 | 1.5 |

| 13.5 | +0.60/+0.30 | 330 | 1.5 | 28.0 | +0.8/+0.3 | 330 | 1.5 |

| 14.0 | +0.70/+0.30 | 330 | 1.5 | 28.5 | +0.8/+0.3 | 330 | 1.5 |

| 14.5 | +0.70/+0.30 | 330 | 1.5 | 29.0 | +0.8/+0.3 | 330 | 1.5 |